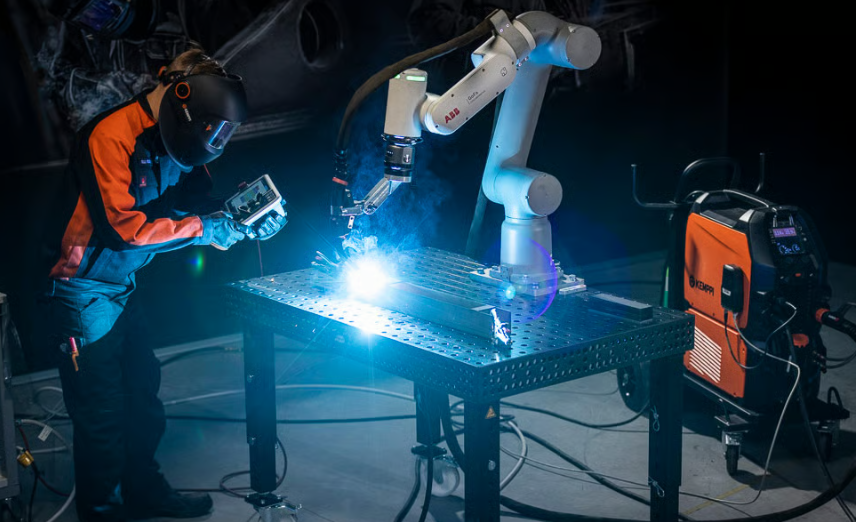

Cobot welding is rapidly transforming the manufacturing landscape by combining precision, efficiency, and safety in a single solution. These collaborative robots work alongside human operators to handle repetitive or hazardous welding tasks, ensuring consistent quality while reducing workplace risks. In this article, we’ll explore how cobot welding can optimize production, enhance productivity, and drive innovation in modern manufacturing.

What is Cobot Welding?

Cobot Welding is the use of collaborative robots (cobots) equipped with welding tools to assist in performing welding tasks. These robots work safely alongside humans using sensors and speed or force limits to prevent injuries. They also automate repetitive or precise welding tasks, making the work faster and more consistent.

Key components

- Cobot arm with a welding torch – the robot can perform the welding motion.

- Welding power supply – can be MIG, TIG, or other types, controlled automatically.

- Sensors – detect collisions, track seams, or guide the welding path to prevent errors.

- Software/user interface – makes it easy to program or guide the robot, sometimes even manually or via a touchscreen.

Applications / Use Cases

- Small to medium manufacturing shops with mixed or low-volume production.

- Automotive parts.

- Metal fabrication.

- Aerospace, where precise welds on specialized materials are important.

See also: What is series square venturessilberlingtechcrunch

Advantages of Cobot Welding

Cobot welding, short for collaborative robot welding, improves manufacturing by allowing robots and humans to work together safely and efficiently. Here are its main benefits:

Better Accuracy and Consistency

Cobots deliver consistent welds, ensuring uniform and high-quality results. By automating repetitive tasks, they also minimize errors caused by human fatigue or inconsistency.

Safer Work Environment

Cobots handle dangerous or repetitive welding tasks and can work safely alongside humans, reducing exposure to heat, sparks, and harmful fumes.

Increased Productivity

Cobots can work faster and longer without breaks, boosting production output. They can also safely share workspaces with humans, allowing easy integration into existing workflows.

Flexible and Adaptable

Cobots are easy to reprogram, allowing them to switch quickly between welding tasks to meet changing production needs. Their flexibility also makes them well-suited for small batches or custom jobs in industries with frequent product changes.

Cobot welding helps make manufacturing more accurate, safe, and productive. It improves quality and efficiency while keeping workers protected.

Considerations When Choosing Cobot Welding

Choose Cobots with an Easy-to-Use Interface

A cobot’s interface affects how fast your team can start using it. Easy-to-use systems need less training and can be operated by welders without programming skills. Modern cobots let operators move the robot arm by hand and adjust settings easily, so welders can focus on welding instead of programming.

Look for Flexibility in Welding Tasks

Select a cobot that can handle a variety of welding jobs, workpiece sizes, and methods such as MIG, TIG, or spot welding. For larger parts, choose one with greater reach and lifting capacity. Ensure it integrates easily with your existing machines and can switch tasks quickly. Flexible cobots are ideal for small-batch production and adapting to changing manufacturing needs.

Prioritize Easy Installation and Maintenance

Select cobots that are quick to set up and easy to maintain. This includes models that can be ready to use shortly after unboxing, have simple servicing, accessible replacement parts, and local support. Modular designs speed up repairs and upgrades, minimizing downtime and maintaining efficiency.

Ensure Stable and Reliable Results

High-quality, consistent welds are essential. Cobots should weld precisely, with minimal variation (around ±0.1mm). Real-time monitoring and adaptive controls help maintain quality even if materials or conditions change. Using proper tools, jigs, and fixtures ensures stable positioning, fewer defects, and less rework.

How Cobot Welding is Transforming Manufacturing

Cobot welding is revolutionizing manufacturing by boosting efficiency, precision, and flexibility. Across industries, these collaborative robots are helping companies produce higher-quality products faster and more reliably. Here’s how different sectors are benefiting:

Automotive & Aerospace

Cobots are widely used to weld components such as seat frames, fuel tanks, suspension arms, and exhaust systems. Their precision and ability to perform repetitive tasks consistently help reduce human error, ensuring uniform quality across production lines.

Metal Fabrication & Industrial Machinery

In metal fabrication, cobots handle structural components, machinery parts, and heavy-duty equipment. Their versatility allows them to work with various materials and welding methods, including MIG, TIG, and arc welding. This adaptability makes cobots ideal for a wide range of fabrication tasks.

Electronics & Precision Components

Cobots are well-suited for delicate welding tasks in electronics, such as assembling connectors, housings, and brackets. Their gentle handling prevents damage to sensitive components, supporting high-quality assembly and reliable device performance.

Small & Medium-Sized Enterprises (SMEs)

SMEs benefit from cobots due to their affordability and easy integration. Cobots automate repetitive welding tasks, improve weld quality, and enhance productivity without requiring major workflow changes. This enables smaller manufacturers to scale operations efficiently.

Cobot welding helps manufacturers achieve consistent, precise, and flexible production across industries. By combining automation with human supervision, cobots enhance quality, safety, and efficiency in various industries.

Challenges and Limitations

High Initial Costs

Setting up a cobot welding system can be costly initially, covering the robot, safety equipment, sensors, and installation. Over time, these costs can be balanced by savings from reduced labor, higher efficiency, and less material waste.

Difficulty with Complex Welds

Cobots are great at repetitive and precise welding, but they can struggle with complex welds that need human judgment and adaptability. This includes parts with uneven thickness, unusual angles, or irregular shapes, which skilled human welders handle more effectively.

Dependence on Proper Programming and Maintenance

Cobots need trained personnel to program them, handle troubleshooting, and perform regular maintenance. Without proper training and care, their performance, efficiency, and reliability can suffer.

Cobot welding enhances productivity and precision but involves high costs, limitations with complex welds, and ongoing maintenance requirements.

Future of Cobot Welding

Cobot welding is improving quickly because of new technologies and changing industry needs. Here are the key trends:

Smarter and More Adaptive Cobots

Cobots use AI and machine learning to work more efficiently. They analyze welding data in real time, optimize performance, and predict maintenance needs. This helps increase productivity and prevent downtime.

Integration with Industry 4.0

Cobots can seamlessly connect with other machines, sensors, and cloud platforms within a smart factory. This connectivity enables real time monitoring, smarter decisions, and predictive maintenance to prevent downtime.

Easier Programming and Deployment

Modern cobots are easy to use and quick to install, needing minimal training. This enables businesses to implement automation smoothly without interrupting daily operations.

Focus on Sustainability

Cobots are being designed to save energy and reduce material waste. This supports sustainable manufacturing practices and aligns with global efforts to make industrial operations more environmentally responsible.

Growing Industry Adoption

More companies, from automotive and aerospace to small and medium-sized enterprises (SMEs), are adopting cobot welding. Their affordability, flexibility, and scalability make them a practical solution for improving productivity and addressing labor shortages.

The future of cobot welding is smarter, more connected, easier to use, environmentally friendly, and widely adopted across industries. These advancements promise more efficient, adaptable, and sustainable manufacturing processes.